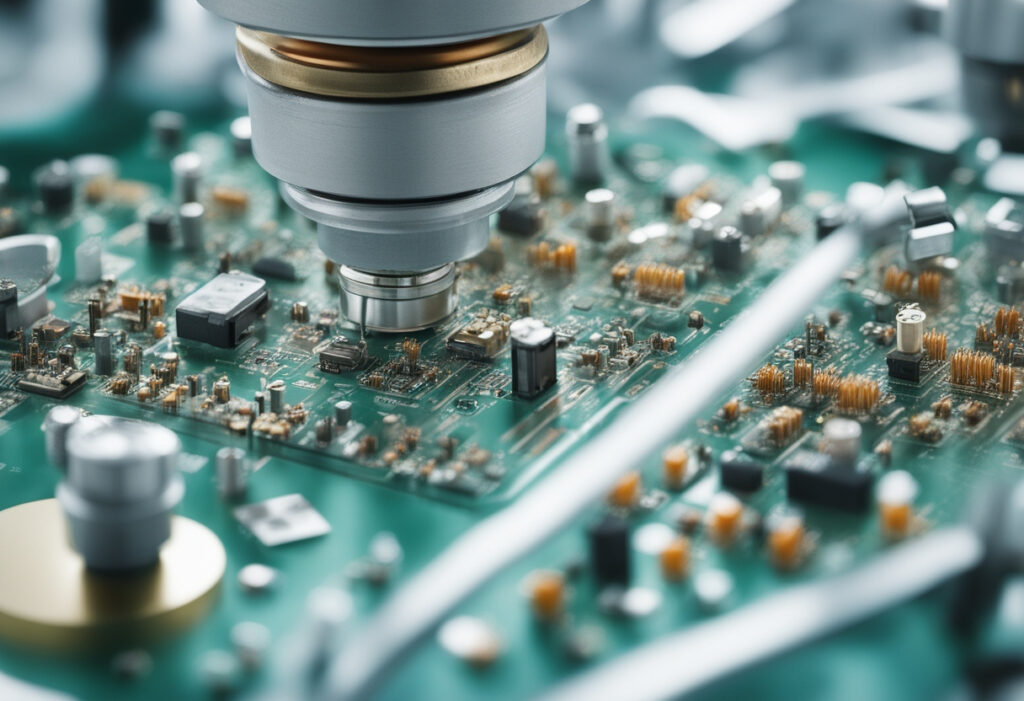

The market for non-wetting and voids quality inspection in manufacturing is on the brink of a major breakthrough, poised for explosive growth as industries demand higher standards of precision and reliability. Non-wetting and voids in solder joints are critical defects that can undermine the performance and durability of electronic components, making advanced inspection solutions indispensable in today’s high-stakes manufacturing landscape.

The surge in sectors such as automotive, aerospace, consumer electronics, and telecommunications is fueling the need for cutting-edge quality inspection technologies. Traditional methods are increasingly proving inadequate, unable to keep pace with the complexities and demands of modern production. Enter Artificial Intelligence and machine learning-game-changing technologies that are transforming the inspection process. AI-powered inspection solutions deliver unprecedented accuracy and speed, providing real-time detection and analysis of non-wetting and voids. This not only ensures impeccable quality standards but also significantly reduces downtime and operational costs.

The future of non-wetting and voids quality inspection is undeniably bright, with AI-driven innovations leading the charge towards greater automation, enhanced reliability, and unmatched efficiency. As manufacturers worldwide strive for perfection, the market is set to experience rapid expansion, marking a new era of excellence in quality control.